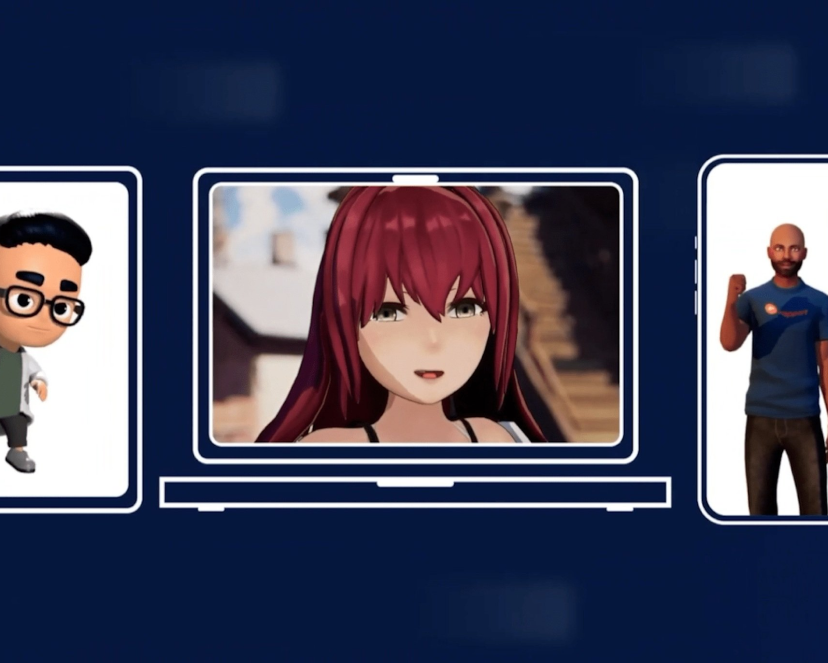

AI avatars for manufacturing

Prepare frontline and operations teams for real-world scenarios through realistic, scenario-based practice — without disrupting production.

How manufacturing uses Rapport

Train workers to respond to real production scenarios

Workers practice conversations and decision-making around equipment issues, quality checks, shift handoffs, and process deviations before they happen on the floor.

Improve safety and incident response readiness

Simulate safety incidents, near-misses, and emergency situations so teams learn how to respond calmly and correctly under pressure.

Standardize processes across sites and teams

Create scenarios once and deploy them across plants and roles so everyone follows the same procedures and quality standards.

Deliver training across shifts, plants, and languages

Run the same scenarios across locations, shifts, and languages simultaneously, ensuring consistent training without duplicating content.

Reduce ramp time for new hires and contractors

New workers rehearse procedures, safety protocols, and common issues repeatedly, helping them reach productivity faster and make fewer mistakes.

Session-level reporting for targeted coaching

Built-in reports show how individuals and teams perform across scenarios, helping supervisors identify gaps and focus coaching where it matters most.

Trusted by leading teams across industries

Customer stories

See Rapport in action

“

Of the systems we tested, Rapport was by far the easiest to use and connects seamlessly with a host of services. Rapport’s facial animation combined with its low latency and real-time responses helps us bring a new level of realism to our Virtual Humans creating truly immersive experiences.”

Nils Hellberg

CTO, Virti

See Rapport for manufacturing in action

You may also like

Stay in the loop with Rapport

Get the latest posts, product updates, and insights delivered to your inbox. No fluff, just the good stuff.